Handling your armored fiber optic cable carefully is vital if you don’t want to damage it during installation. So keep reading for tips on how to manage them.

Did you know that the undersea cables that connect continents can sometimes be as long as 10,000 miles?

Fiber optic cable can reach incredible distances. Thanks to the fact that it uses light to transfer information, it’s the ideal solution for long cable runs in almost any application. Unfortunately, fiber optics have a flaw: they’re fragile.

Optical fiber consists of pure glass. While pure glass can bend and refract light, it’s not the most durable thing in the universe.

Armored fiber optic cable is a solution to the inherent weakness of pure glass. That said, there are some things to keep in mind during fiber optic installation. In this guide, we’ll provide you with some tips on how to handle armored fiber optic cable the right way.

Choose the Right Armored Fiber Optic Cable

Before you begin with installation, you need to be sure your armored fiber cable is up to the job. Not all fiber cable is the same. It pays to know what sort of product your supplier of fiber optic cable is giving you.

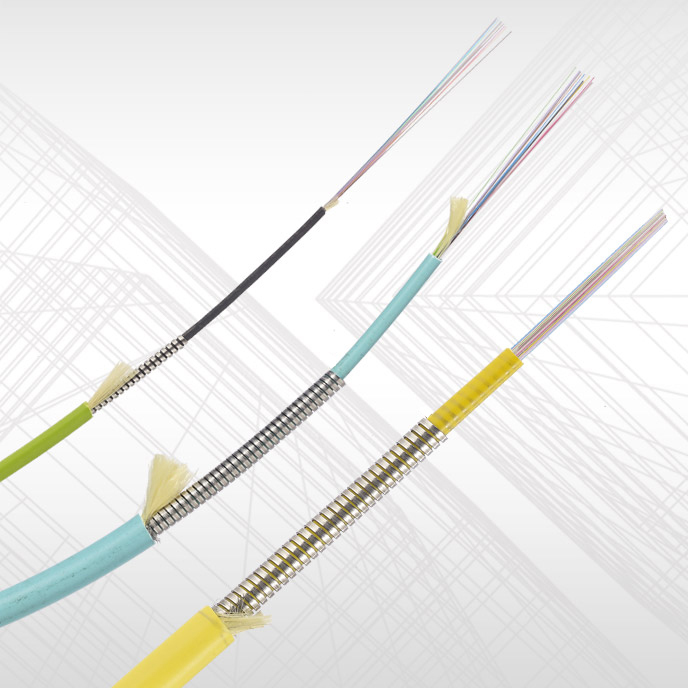

The aluminum interlock armor (also known as AIA fiber optic cable) is a popular option. However, it comes with some serious drawbacks.

First, aluminum interlock armor (AIA) fiber optic cables are heavy. It uses a thick shielding cover, which means spools can weigh much more than competing wires.

This leads to complications during fiber optic installation. It’s more difficult to fit into varying cable runs and requires much more manpower and time to install. The result is a cable that is more expensive, with an installation that is as well.

TiniFiber: The Solution to the AIA Cable

TiniFiber created the stainless steel micro armor fiber optic cable to make up for deficiencies in the AIA cable.

For starters, it’s 75% smaller and 65% lighter than the AIA. That means it takes less time and material to produce. The result is a cable that is more economical without sacrificing any strength.

Second, the micro armor fiber cable is more versatile. It can reach anywhere that the AIA can, and then some. Its smaller profile means it fits into those nooks and crannies that the AIA can’t reach.

That means it takes up less space, leaving more leftover for you to devote to other cables.

Most importantly, the stainless steel micro armor fiber optic cable makes no concessions in strength and durability. The micro armor cable is strong, resistant to everything from chemicals to pests, and most importantly, crush proof.

The AIA lacks the durability that TiniFiber has which means you’ll need to rip it out and reinstall new cable more often.

Now, let’s cover some tips during cable installation.

1. Do Not Pull on the Fibers Themselves, and Understand Their Pull Strength Rating

When installing fiber, it’s key to understand that an armored fiber optic cable doesn’t protect exposed fibers. This may seem like common sense, but it’s all too common for contractors to pull on the delicate internal fibers rather than the outer cable.

In that same vein, know the pull load rating. It’s ideal to start pulling from the middle, rather than the ends since this puts less strain on the cable. Make sure your puller is set to the proper tension reading.

If you’re using lubricants during this process, make sure they’re compatible with your materials.

2. Know the Bend Radius

Again, an armored fiber optic cable cannot make up for the inherent limitations of fiber optic cable. While the armor might be able to bend at a tight angle without suffering damage, this will crush or tear the internal fiber optic cables. Therefore, you need to know the correct bend radius before running a cable around a corner or around an obstruction.

Further, you want to reduce the twist throughout an install. Twist is gradual, and unscrupulous hired hands can introduce it without their realization. When unspooling the cable, ensure that you aren’t introducing twist into the length.

3. Plan the Installation from Start to Finish, and Measure Everything Multiple Times

Fiber optic installation, like any cable installation, can provide infinite contingencies for failure. It’s not just about getting the lengths of each wall right and accounting for fixtures. You need to know the position of equipment, problem areas, and anything that presents a potential safety issue.

It helps to map the fiber out onto a physical space. Your client may have to change their needs as the months and years go by, so you should do everything to accommodate these changes. For example, you may want to install additional outlets for future equipment placements.

Even after you’ve measured everything, you need to keep close track of the spool. You may need to make changes in the heat of the moment when challenges arise. Your people need to monitor the run from multiple points along the way.

Make sure to pull on the cable, and never push it. This is especially true when you have already placed a length of cable. Pushing instead of pulling risks introducing twist and affecting the bend radius, throwing things out of alignment.

A good rule to remember with cable is that you’d rather use too much than too little. You can cut off or roll up excess cable, but not having enough will force you to cut into cable back down the line. This looks terrible, introduces more complications, and costs more money and time.

Source Your Cable from TiniFiber

Armored fiber optic cable provides needed strength to a medium that comes with inherent weaknesses. However, even the best armored fiber optic cable is limited by the inadequacies of the internal fibers. Keep the above tips in mind when performing your installation to ensure that all goes well.

TiniFiber is the leader in armored fiber cable. Request a sample of their industry-leading armored cable today, and see for yourself the difference it can make.