AIA

Micro Armor Fiber™

The world’s most versatile and armored optical cable for any application

The original Micro Armor Fiber™

Outdoor Fiber Cables >

Indoor/Outdoor Fiber Cables>

Indoor Fiber Cables >

Hybrid Power Cables >

TiniFiber Applications

Industrial / Factory Floor

Broadband & Residential

Transportation

Armored Fiber Optic Cables

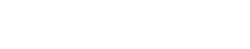

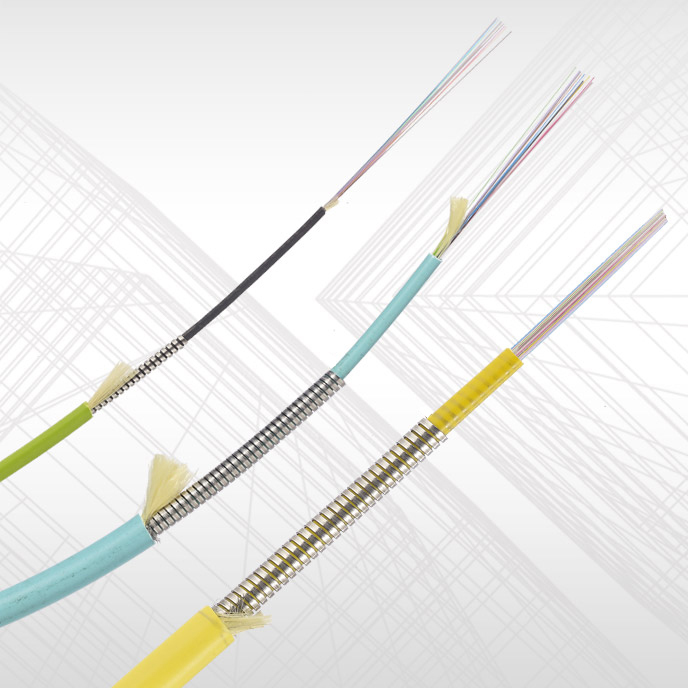

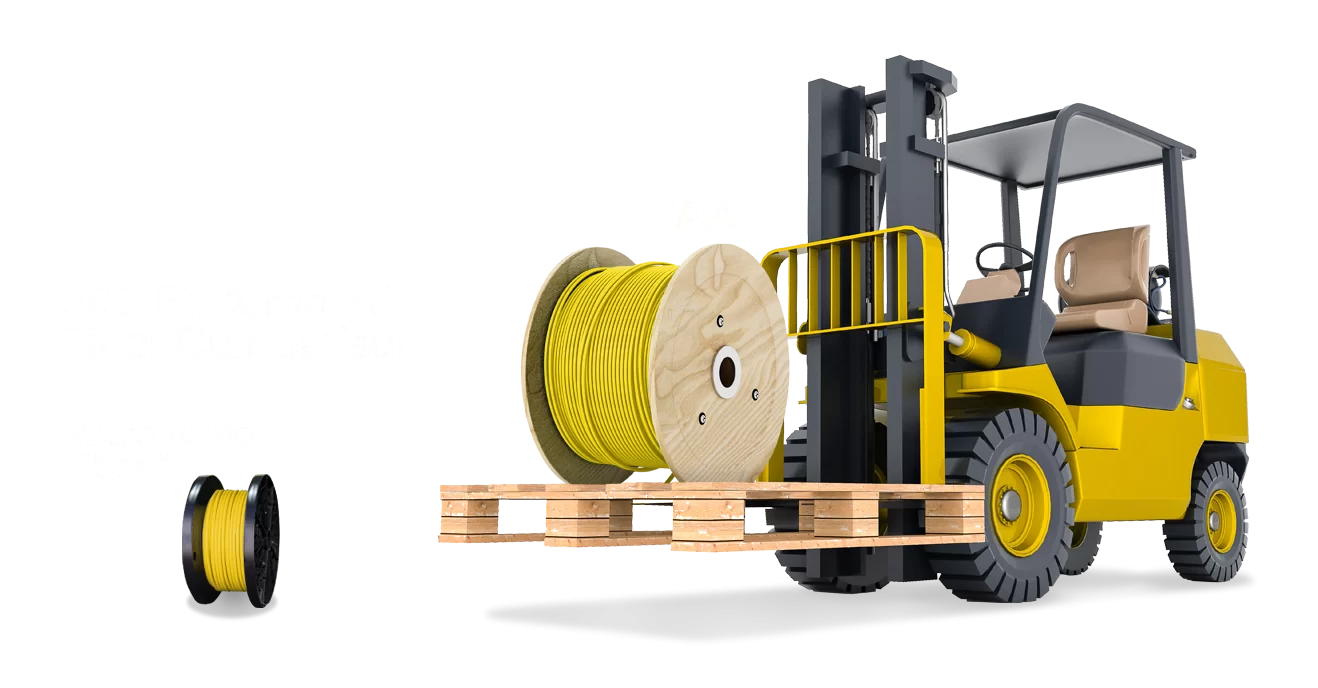

With the smallest Outer Diameter of any armored fiber optic cable, TiniFiber® can be easily pulled through the tightest, curviest and most congested pathways for significant time and labor savings. It’s ideal for aerial, underground and powered applications including reclamation of conduit. Its tiny size, light weight and flexibility deliver outstanding savings in installation time, labor, shipping and warehousing costs.

The TiniFiber® Difference

For the first time in over 20 years, the industry has an innovative alternative to conventional Aluminum Interlock Armor (AIA) – TiniFiber®. This 75% smaller, 65% lighter fiber optic cable gets its superior durability, flexibility and adaptability from its patented Micro Armor stainless steel coil, which is designed to protect the glass strands and bend radius.

News & Articles

TiniFiber® Welcomes Tom Brown as Vice President of Business Development

Tom's appointment positions TiniFiber for market expansion and growth in data...

TiniFiber® and OmniCable Form a Strategic Partnership to Expand Availability of Micro Armor Fiber®

Cabling Solutions Aims to Revolutionize and Streamline Distribution Across...

TiniFiber® to Showcase Revolutionary Micro Armor Fiber™ Cable at OFC 2024

Visitors will discover an armored fiber optic cable that is 65% smaller and...

TiniFiber® Expands Team Across North America

Strategic appointments support increased sales and strengthen company as key...